Description

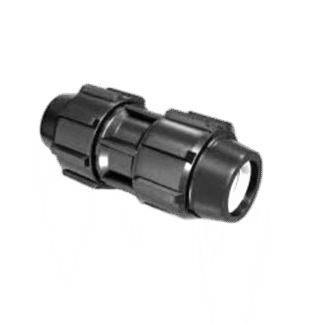

Polyethylene Splinter Belt

Polyethylene Splinter Belt is one of the types of polyethylene fittings. this product are used to split the side pipes and main pipes as well as repair pipes. this product has two main parts: floor and branch. That can have different genders. This product is closed around the polyethylene pipe with the help of bolts.

How to install polyethylene belt

At first, we open two belts and wrap around the polyethylene pipe and then we tie them together with the help of bolts. So that the pipe is tightened around it. Then, the part of the polyethylene pipe on which the belt umbilical cord is placed is punctured by special tools and the fastener or metal is attached to the belt.

Types of splinter belts

Based on the size and type of consumption, the polyethylene belt can be divided into the following grouping.

1- Normal belts from 20 mm to 315 mm

2- Polyethylene camry with brass brain

3- Asbestos Splinter Belt

4- Cast iron and steel split belts that can be produced in flanged form.

Advantages

It has high flexibility at the same time strong.

It is resistant to long-lasting sunlight as well as ultraviolet radiation.

Installation is easy and affordable.

This product is used for a variety of polymer pipes of different sizes, polyethylene fittings are used in drip irrigation piping system.

It has sizes ranging from 20 to 315 mm for different atmospheric pressures such as 10 atmospheres.

Uses

Polyethylene belts are used in various cases such as agriculture, urban and rural drinking water transfer for drip and sprinkler irrigation and more. But the most commonly used of this product is in the agricultural industry and drip irrigation, which is used to install a variety of riser, sprinkler, gradual valves such as: valves and connections to drip polyethylene pipes or folding pipes and polyethylene.

Reviews

There are no reviews yet.