Description

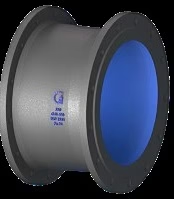

Flanged socket pn=10 atm

Flanges socket are used when the piping joint needs dismantling. Flanged socket are used mainly at equipment’s, valves and specialties. In certain pipelines where maintenance is a regular feature, breakout flanges are provided at definite intervals. A flanged joint is composed of three separate and independent although interrelated components; the flanges, the gaskets and the bolting. Special controls are required in the selection and application of all these elements to attain a leak-proof joint.

Slip On Flange –

The Slip On type flanges are attached by two fillet welds, inside as well as outside the flange. The calculated strength from a Slip On flange under internal pressure is of the order of two-thirds that of Welding Neck flanges, and their life under fatigue is about one-third that of the latter. Normally, these flanges are of forged construction and are provided with hub. Sometimes, these flanges are fabricated from plates and are not provided with the hub.The disadvantage of the flange is that a combination of flange and elbow or flange and tee is not possible because named fittings have not a straight end that complete slid in the Slip On flange

Socket Weld Flange –

The Socket weld flanges are attached by only one fillet weld, only on outside, and are not recommended for severe services.

- These are used for small-bore lines only. Their static strength is equal to Slip On flanges, but their fatigue strength is 50% greater than double-welded Slip On flanges.

- The thickness of connecting pipe should be specified for this type of flanges to ensure proper bore dimension.In socket weld flange, before welding, a space must be created between flange or fitting and pipe.

- ASME B31.1 Preparation for Welding (E) Socket Weld Assembly says:In assembly of the joint before welding, the pipe or tube shall be inserted into the socket to the maximum depth and then withdrawn approximately 1/16″ (1.6 mm) away from contact between the end of the pipe and the shoulder of the socket.

- The purpose for the bottoming clearance in a Socket Weld is usually to reduce the residual stress at the root of the weld that could occur during solidification of the weld metal. The image shows you the X measure for the expansion gap.

- The disadvantage of socket weld flange is right the gap, that must be made. By corrosive products, and mainly in stainless steel pipe systems, the crack between pipe and flange can give corrosion problems. In some processes this flange is also not allowed.

Reviews

There are no reviews yet.