Description

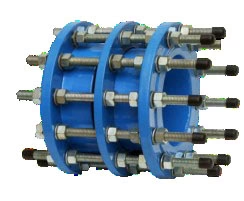

cast iron Dismantling joints with cold galvanized bolts

One of the most important products in the water transmission network is the cast iron Dismantling joints , one of the pipeline attachments, which can be used to separate the valves from pipelines and reduce the length of the piece during the implementation through the bolts so that there will be room to separate the valves and sealing gaskets when installing the valve and sealing gasket again. The length of the fittings can be adjusted with the help of screws and nuts and the valves can be tightened between the flanges.

These fittings play an important role in the design and layout of pipelines. The ease of installing and fine-tuning the valve in the existing pipeline without using these connections will be very difficult.

Rapid installation and implementation, increased work efficiency and reduced working time are among the advantages of this product.

This product can also be used to connect different parts of pipelines to each other and fill up empty space.

This product is produced in sizes from 50 to 1000 mm

Disadvantages of cast iron Dismantling joints

Due to the cast iron, this product has a heavy weight and it is hard to transport in the gargah.

Cast iron fittings are produced in different sizes from 50 mm to 1000 mm and to the wings these connections increase the costs of transmission projects.

Cast iron connections break early in the face of sudden impacts.

Advantages

The advantages of cast iron fittings are 1- its resistance to corrosion

2- Resistance to high temperatures

3- Resistance to high pressures and negative pressures

4- Abrasion resistance mentioned

5- Resistance to external pressures such as

Climate change, which is the reason for the expansion and contraction of the connection, causing connections to fail

Climate change, which is the reason for the expansion and contraction of the connection, causing connections to fail

Reviews

There are no reviews yet.